How Do Embroidery Machines Work? Beginner's Guide Explained

A Full Beginner’s Guide to Modern Embroidery Technology

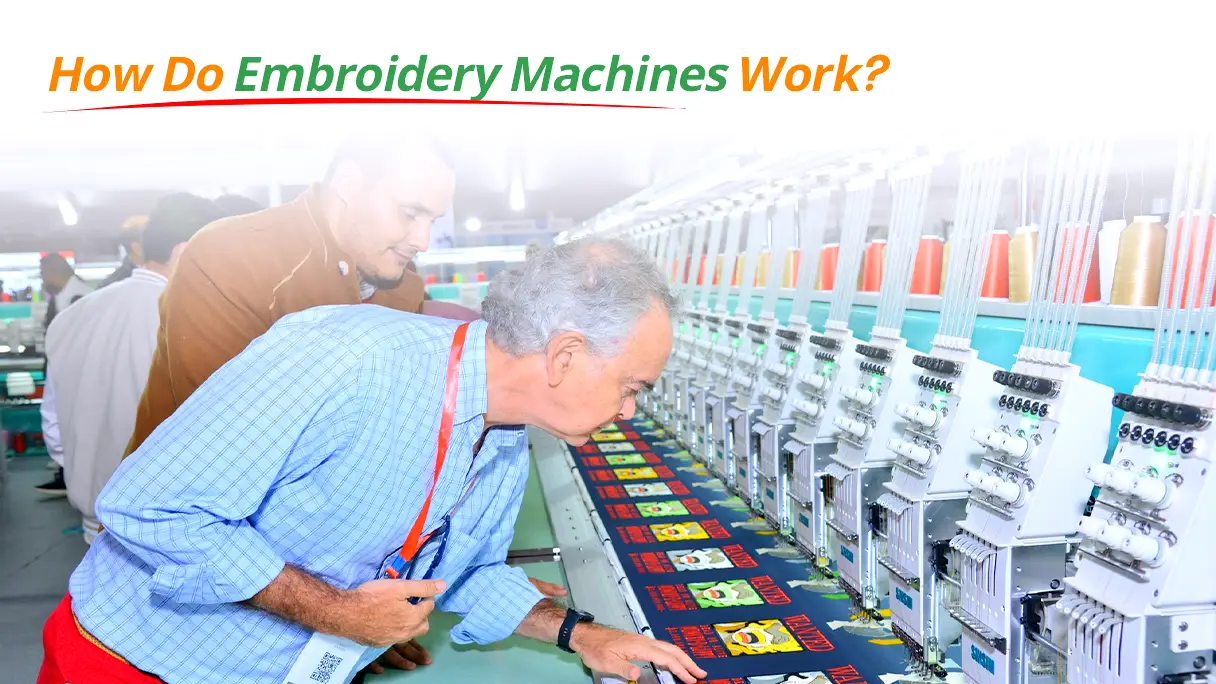

Embroidery machines have transformed the textile and garment industry—turning complex, time-consuming hand embroidery into fast, precise, and repeatable production. Today, manufacturers and brands around the world rely on advanced embroidery solutions from industry leaders like SINSIM Bangladesh, known for delivering modern, high-performance embroidery machines.

Whether you’re a beginner exploring embroidery for the first time or a business planning to invest in industrial equipment, understanding how embroidery machines work is the first step toward mastering this technology.

What Is an Embroidery Machine?

An embroidery machine is a specialized sewing machine designed to automatically create decorative stitching patterns on fabric. Unlike traditional sewing machines, embroidery machines follow digital design files to stitch logos, text, patterns, and artwork with exceptional accuracy.

Modern embroidery machines—such as those supplied by SINSIM embroidery machine solutions—are widely used in:

-

Garment factories

-

Fashion and apparel brands

-

Promotional merchandise production

-

Home-based embroidery businesses

-

Textile and accessories manufacturing

The Basic Working Principle of an Embroidery Machine

At its core, an embroidery machine works by synchronizing needle motion, thread control, and fabric movement based on a digital design.

Here’s how the process works step by step:

-

A digital embroidery design is loaded into the machine

-

Fabric is secured tightly using a hoop or frame

-

The machine reads stitch data from the design file

-

Needles move vertically while the frame moves horizontally (X-Y axis)

-

The design is stitched automatically with consistent precision

High-quality machines from brands like SINSIM Bangladesh are engineered to maintain accuracy even at high speeds, ensuring clean embroidery and minimal errors.

Main Components of an Embroidery Machine

Understanding the core components makes it easier to see how embroidery machines operate as a complete system.

1. Control Panel / Computer System

This is the machine’s control center. It:

-

Reads embroidery design formats (DST, DSB, etc.)

-

Controls stitch speed, direction, and color changes

-

Allows design editing, scaling, and positioning

Modern SINSIM embroidery machines feature advanced touchscreen panels with USB, network support, and onboard memory for production efficiency.

2. Needle System

Embroidery machines use specialized needles designed for continuous, high-speed stitching. Industrial machines typically feature:

-

Single-needle systems for simple tasks

-

Multi-needle systems (12, 15, or more colors) for complex designs

Multi-needle configurations reduce downtime and increase productivity—an essential feature in commercial embroidery.

3. Thread Tension Mechanism

Thread tension controls stitch quality. The machine balances:

-

Upper thread tension

-

Lower (bobbin) thread tension

Well-calibrated tension systems, such as those found in SINSIM embroidery machines, help prevent thread breakage, looping, and fabric distortion.

4. Bobbin System

The bobbin supplies the lower thread that locks each stitch. Industrial embroidery machines use:

-

Large-capacity bobbins

-

Automatic or semi-automatic bobbin winding systems

This allows long production runs with fewer interruptions.

5. Hoop or Frame System

Hoops and frames hold fabric firmly in place during embroidery. Different frames are used for:

-

Caps and hats

-

T-shirts and garments

-

Jackets and thick fabrics

-

Large textile panels

Industrial embroidery machines from SINSIM Bangladesh use precision motor-driven frames for accurate fabric movement.

6. Motor and Drive System

Servo motors control:

-

Needle movement

-

Frame positioning

-

Stitch speed and consistency

This motor system enables modern embroidery machines to operate at thousands of stitches per minute while maintaining design accuracy.

How Digital Embroidery Designs Work

Embroidery machines don’t “draw” images—they follow stitch instructions.

Step 1: Design Digitizing

Artwork is converted into embroidery stitch data using digitizing software.

Step 2: Stitch Programming

Each stitch includes instructions for:

-

Stitch type (satin, fill, running)

-

Stitch length and angle

-

Color sequence

Step 3: Machine Execution

The embroidery machine reads the file and executes the stitches precisely. High-end systems used by SINSIM embroidery machines ensure smooth transitions and accurate stitching.

Types of Embroidery Machines

1. Mechanical / Manual Embroidery Machines

-

Limited automation

-

Mostly used for learning or basic embroidery

2. Computerized Home Embroidery Machines

-

Digital design support

-

Suitable for small businesses and hobbyists

3. Industrial Embroidery Machines

-

Multi-needle and multi-head systems

-

High-speed production capability

-

Designed for factory-level output

SINSIM Bangladesh specializes in industrial embroidery machines built for scalability, speed, and long-term reliability.

How Multi-Needle Embroidery Machines Work

Multi-needle embroidery machines are designed for efficiency:

-

Each needle is assigned a different thread color

-

The machine switches needles automatically

-

No manual rethreading is needed

This feature is especially important in logo embroidery, fashion branding, and mass garment production.

Advanced Features in Modern Embroidery Machines

Today’s embroidery machines include advanced technologies such as:

-

Automatic thread trimming

-

Thread break detection

-

Laser positioning systems

-

High-speed control panels

-

Network-based design transfer

Modern SINSIM embroidery machines integrate these features to improve productivity and embroidery quality.

Why Embroidery Machines Are Essential for Modern Textile Production

Embroidery machines offer:

-

Consistent quality

-

Faster production

-

Reduced labor dependency

-

Scalable manufacturing

For businesses looking to grow, investing in reliable embroidery technology—like machines supplied by SINSIM Bangladesh—is a strategic long-term decision.

Final Thoughts

Embroidery machines work by combining digital design intelligence, mechanical precision, and automated control systems. For beginners, understanding this process removes confusion and builds confidence—whether you’re starting a business or expanding production.

With trusted industry solutions from SINSIM embroidery machine technology, manufacturers can achieve precision, speed, and consistent embroidery quality in today’s competitive textile market.

Looking for industrial embroidery machines in Bangladesh? Contact SINSIM Bangladesh for expert guidance and reliable solutions.